Caitu degradation

Caitu organic coating is covered on the surface of the protection, can effectively prevent corrosion under the coating substrate, caitu chooses board also has the corresponding corrosion resistance of coating. Caitu, therefore, the corrosion process of degradation mainly includes the coating and substrate corrosion two aspects, the first is the deterioration of paint film and fall off, and then the corrosion of substrate.

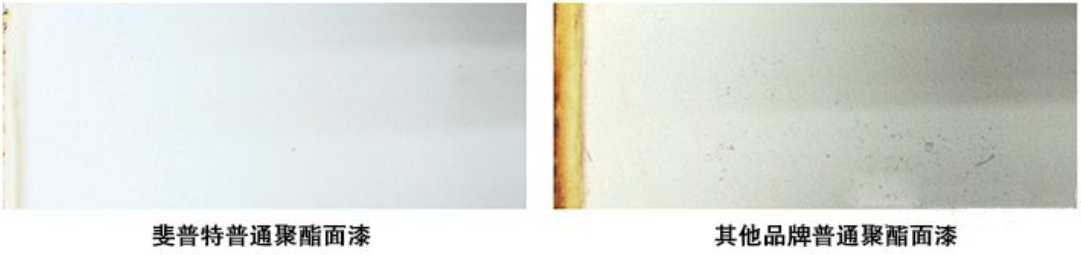

In the general environment, caitu degradation process first show the gloss is reduced, and then from the surface cause discoloration and pulverization, finally is due to the degradation of the resin decomposition, the coating fall off. After peeling coating, lose protection substrate, corrosion will happen again galvanized layer, and then there are the steel corrosion.

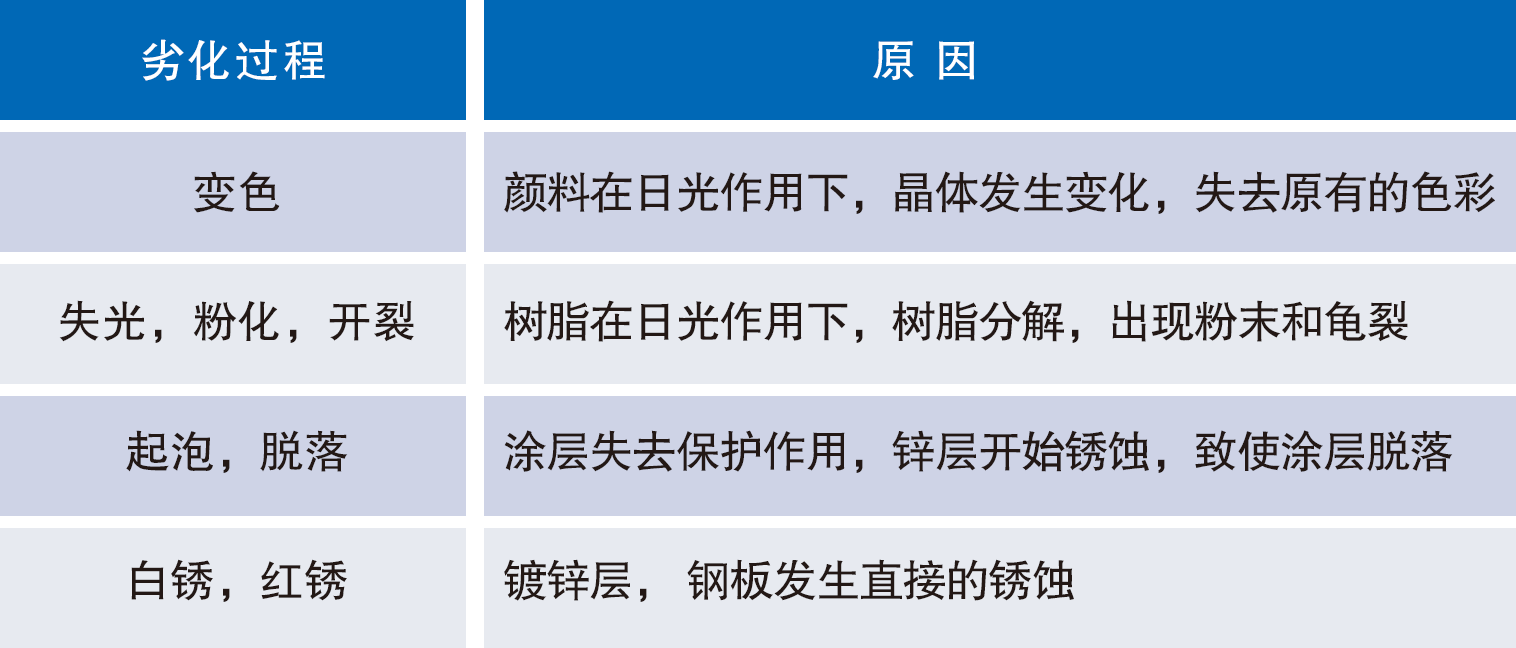

The degradation process

Loss of light - > fade -- -- > pulverization surface crack foaming off -- -- > > coating white/red rust

The experiment content and results

Acid and alkali resistant experiment

The principle of

The sample in a certain concentration of acid/base solution impregnation time, comes out to assess the change of off color, luster and whether there is a discolouration, foaming, fall off wait for a phenomenon.

The results of

Carried out in accordance with the GB/T 1766 samples on loss of light level, color level, foaming, fall off grade evaluation, such as parallel sample take the worst value is the result of the experiment test results.

The Fijian put caitu acidproof alkali experimental results

Test conditions: 5% hydrochloric acid, 5% sodium hydroxide, soaking for 24 hours at room temperature.

Test standard: GB/T 13448-2006 color coating steel plate and steel belt test method

Assessment standard: GB/T 1766-2008, paint and varnish coating aging rating method

Resistant to salt spray test

The principle of

Specimen exposed to the neutral sodium chloride salt fog to a certain time, the surface bubbles, corrosion level and corrosion evaluation spread distance, etc.

The results of

1. For the tablet sample, according to GB/T 1766 sparkling rating, rusting grade, etc., take the worst value of parallel sample experimental results

2. For his fork and notched specimen, select a representative area on line, in the position of at least six equidistance, measuring line until frothy and corrosion of the maximum corrosion spreading distance, take the arithmetic average, is the average corrosion spread distance. Minimum and maximum corrosion and record line spread distance

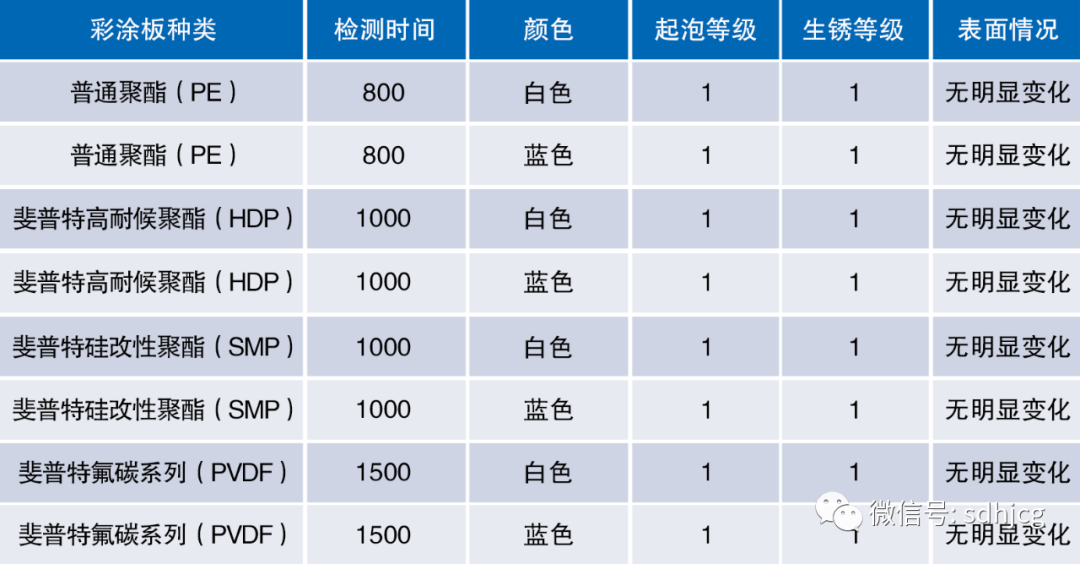

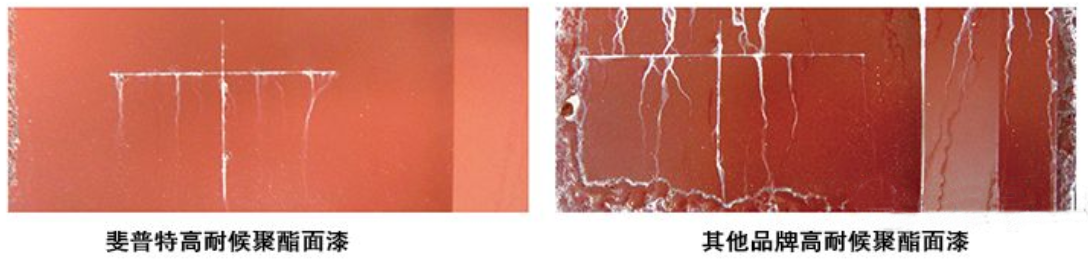

The Fijian put caitu neutral salt spray test results

Test conditions: 5% NaCL, 35 plus or minus 2 ℃ continuous spray

Test standard: ASTM B117-2003 salt spray test standard method

Assessment standard: GB/T 1766-2008 clean paint and coating aging rating method

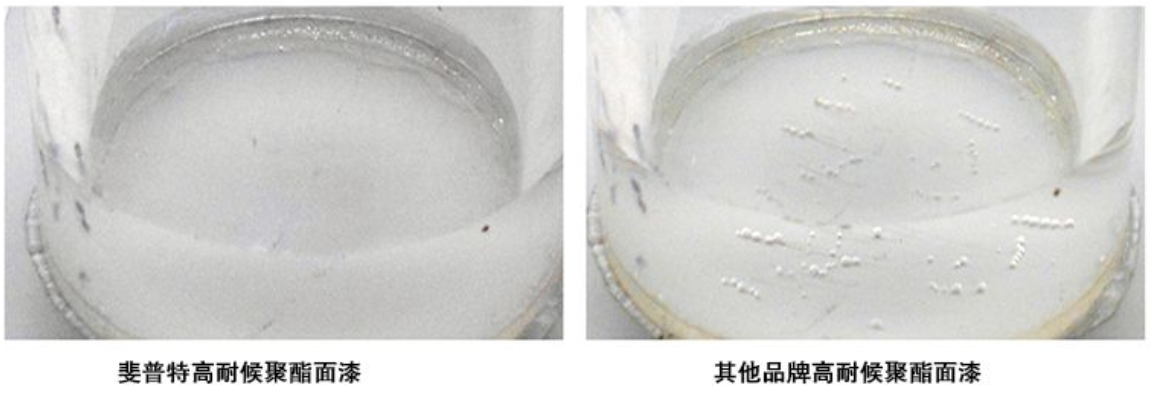

Uv lamp accelerated aging test

The principle of

Any condensation test is exposed to ultraviolet light and (or) atmosphere, after the specified test period, measuring its luster, color, and assess its color light aging, such as powder coating

The results of

According to GB/T 1766 evaluation sample color level, loss of light level and so on, take the worst value of parallel sample experimental results.

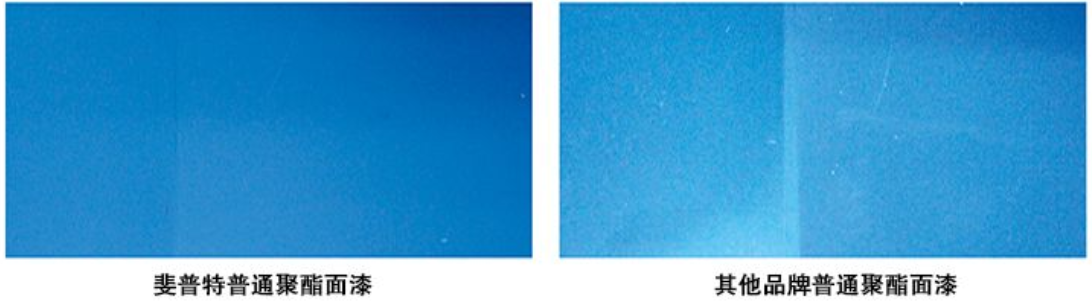

The Fijian put caitu uv lamp accelerated aging test results

Test conditions: UVA light source - 340, 0.77 W/(m2) nm)

Eight hours of ultraviolet light, the blackboard temperature 60 + 3 ℃; 4 hours condensing, blackboard 50 + 3 ℃ temperature

Test standard: GB/T 13448-2006 color coating steel plate and steel belt test method

Assessment standard: GB/T 1766-2008, paint and varnish coating aging rating method

Damp and hot experiment

The principle of

By using non-condensable damp and hot, place the test sample in the temperature of 50 + 2 ℃, relative humidity of not less than 98% in a closed chamber, using the model and the surrounding steam only a very slight difference in temperature between the condensate is formed on the model, to evaluate the sample coating ability of resistance to water penetration.

The results of

According to GB/T 1766 to evaluate the sample blister, cracking, corrosion level, take the worst value of parallel sample test results.

Fiji put light of damp and hot test results

Test conditions: temperature of 50 + 2 ℃, relative humidity of 98% or more of closed chamber.

Test standard: GB/T 13448-2006 color coating steel plate and steel belt test method

Assessment standard: GB/T 1766-2008 clean paint and coating aging rating method